Welcome To

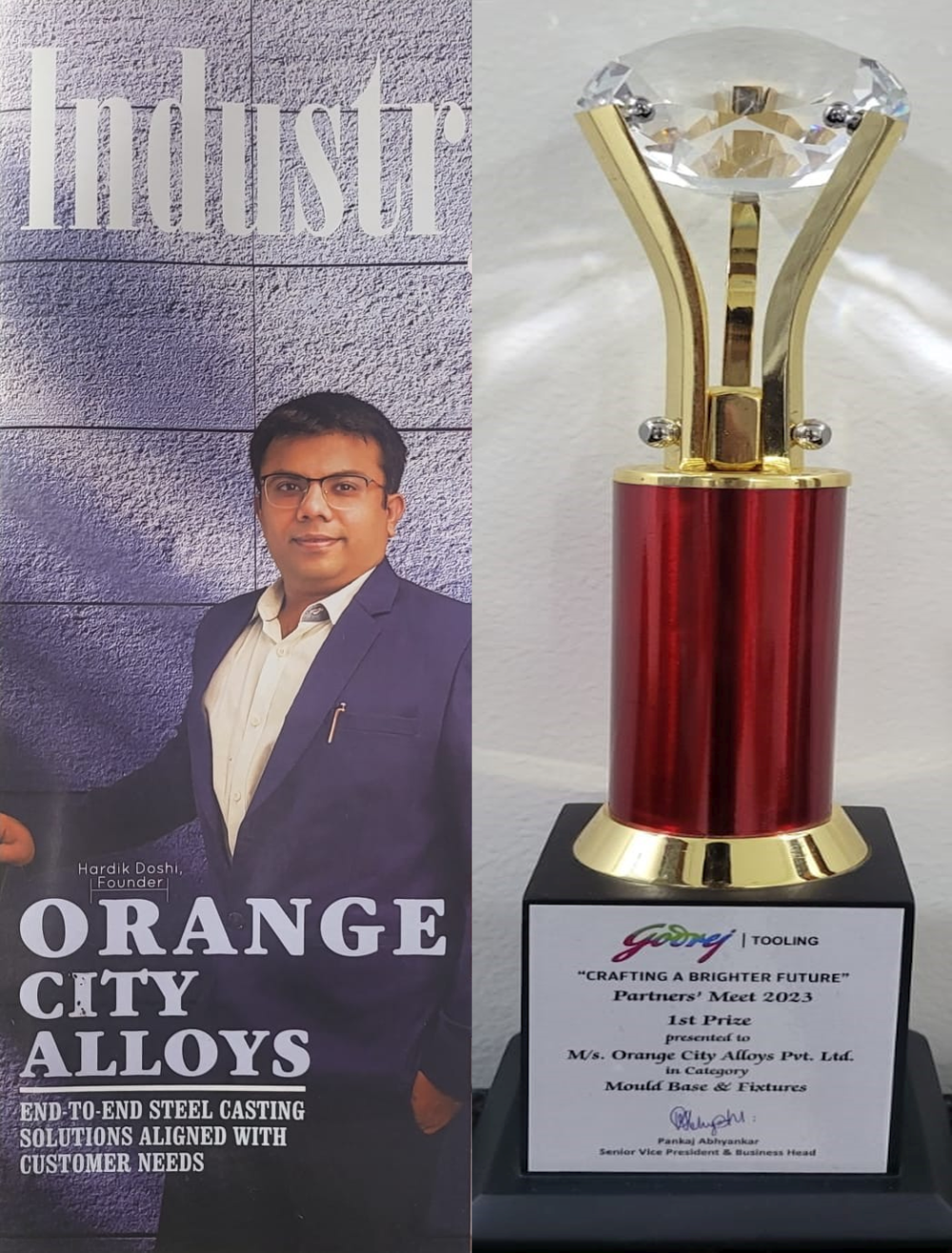

Orange City Alloys Pvt. Ltd.

The leader in Steel Castings and the first choice for Mould base

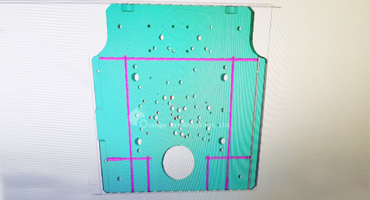

Orange City Alloys Pvt Ltd is a leading manufacturer of Steel Casting , Alloy Steels casting and Dies and Moulds

The company incorporated in 2005 for manufacturing of steel casting and in 2017 started with manufacturing of Mould bases.

The company is an ISO 14001:2015 and also certified with Indian boiler regulation (IBR), American Bureau of Shipping (ABS), Indian register of Shipping ( IRS ) etc.